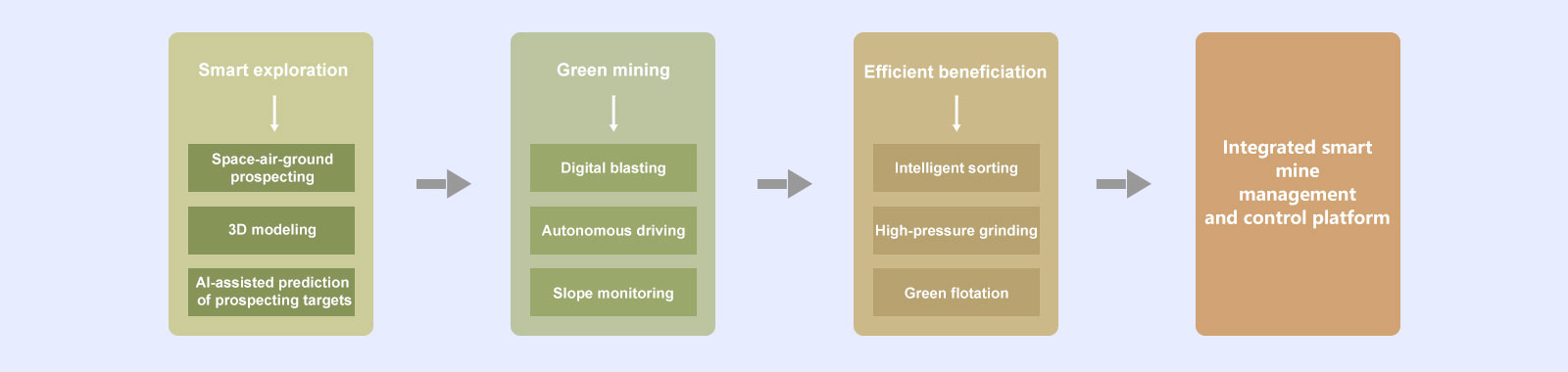

Technology acts as the core engine driving the modernization of the mining industry. PURIDA is committed to systematically integrating cutting-edge exploration theories, intelligent equipment, and environmentally friendly processing technologies into our projects to build up-to-date smart mines. By carrying this out along the entire industrial chain — mine discovery, exploration, mining, beneficiation, and smelting — PURIDA accelerates the intelligent transformation of mining practices. This strategy enables the creation of safer, more efficient, and more sustainable mining production supply chains, setting benchmarks for local enterprises and an example for propelling and promoting mining development in the host countries where our projects are based. Our technical approach centers on the 4 pillars of “Precision Discovery, Green Mining, Efficient Beneficiation, and Clean Smelting”. Through the “Smart Mine” concept, we will ultimately demonstrate strong competitiveness and resilience. By delivering practical implementation cases for smart mine exploration technology and construction platforms, we showcase a complete closed-loop model of “Technology - Platform - Benefits”.